11 Aug,2025

Centrifugal Casting Stainless Steel: Precision and Durability in Industrial Manufacturing

Centrifugal casting stainless steel is a highly efficient metal-forming process that produces superior-quality cylindrical components with enhanced mechanical properties.

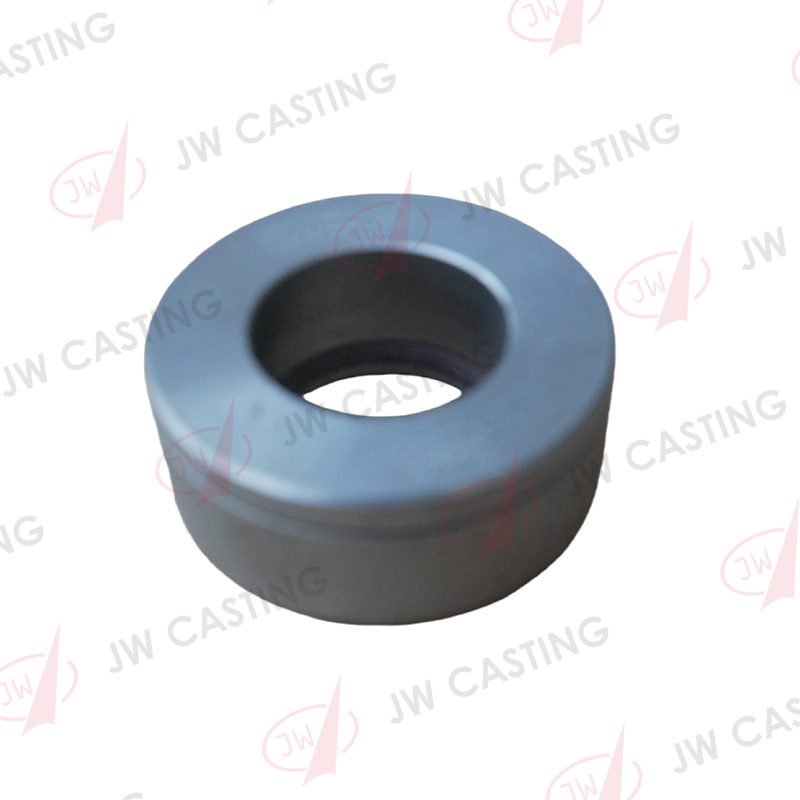

Centrifugal casting stainless steel is a highly efficient metal-forming process that produces superior-quality cylindrical components with enhanced mechanical properties. This method leverages centrifugal force to distribute molten stainless steel evenly, resulting in dense, defect-free structures ideal for demanding applications.

One major advantage of centrifugal casting stainless steel is its ability to create seamless tubes and pipes with uniform wall thickness. Industries such as oil & gas, chemical processing, and aerospace rely on this technique for corrosion-resistant, high-strength parts. The process also minimizes material waste, making it cost-effective for large-scale production.

Compared to traditional casting, centrifugal casting stainless steel delivers finer grain structures and improved metallurgical integrity. This ensures exceptional resistance to heat, pressure, and wear—critical for components like hydraulic cylinders and industrial rollers.

Quality control is paramount in centrifugal casting stainless steel, with advanced testing methods ensuring compliance with ASTM and ASME standards. Manufacturers worldwide trust this method for its repeatability and performance consistency.

In summary, centrifugal casting stainless steel remains a top choice for industries requiring precision, durability, and reliability. Its unmatched material properties and efficiency solidify its role in modern engineering solutions.